Integral 3-Spiral Blade Stabilizer,Integral 4-Spiral Blade Stabilizer(string type& near bit type).The working hardfacing surface(also called as wall contact)materials available separately are(1)carbide insert,(2)Inserted diamond compound,(3)Low temperature brazing tungsten carbide slug,(4)Surface bead welding abrasive welding rod etc..

Through Ultrasonic testing and Magnetic testing the bodies are proved up to grade.

Specifications | ||||||||

钻头直径 | 工作外径Working O.D. | 打捞径外径 | 内径 | 长度 | 两端螺纹类型 | |||

钻柱型 String type | 井底型Near bit type | |||||||

上端Top | 下端Down | 上端Top | 下端Down | |||||

5-1/2 | 140 | 121 (4-3/4) | 50.8 | 1520 | NC38 | 3 1/2 REG | ||

6 | 152.2 | |||||||

6 1/4 | 158.7 | |||||||

6 1/2 | 165.1 | |||||||

7 1/2 | 190.5 | 159 | 57 | 1600 | NC46 | 4 1/2 REG | ||

7 7/8 | 200 | |||||||

8 3/8 | 212.7 | 159 | 71 | 1600 | NC46 | |||

165 | 1800 | NC50 | ||||||

8 1/2 | 215.2 | 159 | ||||||

165 | ||||||||

8 3/4 | 222.2 | 178 | ||||||

9 1/2 | 241.3 | 1600 | NC50 | NC50 | NC50 | 6 5/8 REG | ||

9 5/8 | 244.5 | 178 | ||||||

9 7/8 | 250.8 | 197 | 1800 | 6 5/8 REG | ||||

12 1/4 | 311.2 | 203 209 | ||||||

16 | 406 | 229 | 76 | 1800 | NC56 | NC56 | NC56 | 6 5/8REG |

6 5/8REG | 6 5/8REG | 6 5/8REG | ||||||

17 1/2 | 444.5 | 2000 | NC61 | NC61 | NC61 | NC61 | ||

24 | 609.6 | 2200 | 7 5/8REG | 7 5/8REG | 7 5/8REG | 7 5/8REG | ||

26 | 660.4 | |||||||

28 | 711.2 | |||||||

Hardfacing

HF 1000

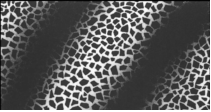

Crushed tungsten carbide held in a nickel bronze matrix. The

3 mm grain size ensures greater concentration of carbide

which is ideal for soft formation drilling.

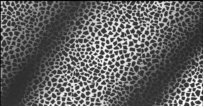

Sections through hardfacing.

HF2000

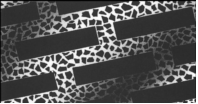

Trapezoidal tungsten carbide inserts held in a sintered carbide

nickel bronze matrix. This will give a greater depth of carbide

coverage – ideal for high deviation drilling in abrasive

formations.

![]()

Sections through hardfacing.

HF 3000

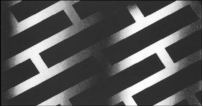

Tungsten carbide inserts set in a powder spray deposit ideal

Tungsten carbide inserts set in a powder spray deposit ideal

for abrasive formations. 97% bonding guaranteed, certified by

ultrasonic report. Recommended for non- magnetic stabilizers.

![]()

Sections through hardfacing.

HF 4000

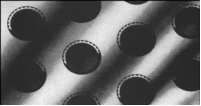

Tungsten carbide inserts (button type). The inserts have been developed to allow cold insertion and maintain close fit. A greater concentration of inserts on the bottom third of the blade and leading edge will increase surface contact to reduce wear in highly abrasive formations.

Tungsten carbide inserts (button type). The inserts have been developed to allow cold insertion and maintain close fit. A greater concentration of inserts on the bottom third of the blade and leading edge will increase surface contact to reduce wear in highly abrasive formations.

![]()

Sections through hardfacing.

HF 5000

This oxy-acetylene process applies tough molten carbide particles of varying sizes held in a nickel chrome matrix which provides excellent bonding properties and greater surface ear characteristics are achieved. Surface hardness levels over 40 HRC. Idear for GEO-THERMAL applications over 350°

![]()

Sections through hardfacing